A brief history of the wool trade in the Witney area

Wool and woollen cloth making has been an important trade and industry in the Cotswolds and West Oxfordshire for hundreds of years. This was mainly because the local landscape is made up of large areas of open limestone grasslands or hill pasture which is very good for breeding and grazing sheep. Witney itself was sited on a fast flowing river useful for powering cloth-fulling mills and it also had good road networks connecting it with important trading centres [1].

Iron Age

A loom weight found on an archaeological excavation from

Oxfordshire.

Roman

When they settled in Britain after AD43, the Romans took advantage of the local resources, making and trading woollen products. Excavations at Shakenoak Roman Villa, North Leigh (near Witney) revealed bone combs that were used to prepare raw wool ready for spinning.

'Cotswold Lion' sheep.

Saxon

The Saxons were skilled makers of woollen cloth, and exports of English sheepskins, wool and cloth goods were already taking place by Saxon times [2]. The very name 'Cotswold' is thought by some to be made up of two Saxon words: 'cote' meaning sheep fold and 'wold' meaning bare hill.

Norman

The Domesday Book mentions weaving and connected trades as taking place in the Witney area; it was commissioned by William the Conqueror in 1086 to find out how much land and resources were owned in England so that he could raise tax on them.

Written records dating from sometime before the Norman invasion support the evidence that weaving as a cottage industry existed in the region from an early period

Medieval

The Medieval economy of the Cotswolds was largely based on the allied trades of sheep farming and cloth production. Until mechanisation really took hold in the local textile industry in the early 19th century, many of the stages in cloth making were carried out as a cottage industries. People worked in their own homes on different tasks including sorting, carding, spinning and weaving.

The fulling of cloth however was carried out in mills sited on the River Windrush. This was where the newly woven, greasy cloth was washed and shrunk down to clean and thicken up the texture of the material.

12th century

A page from a Medieval illuminated manuscript showing a man

shearing a sheep.

Much the wool from these flocks was exported to Flanders, which was then a big weaving centre, but it also seems to have encouraged a local weaving industry to develop [3]. We know that weavers were certainly working in the town by the end of the 12th century because a fine imposed on a Witney weaver is recorded in the Royal Pipe Rolls of 1179.

13th century

The 13th century sees wool becoming more important in and around Witney; at least three local fulling mills had been built by this time, including Farm Mill [4].

The Bishops of Winchester continued to increase the sheep flocks they held on their Witney lands so that they were almost 1,500 sheep strong by the end of the 14th century [5]. By this time the Bishops had established Witney as a collection and storage centre of wool coming from their local manors before it was sold and exported [6].

14th and 15th centuries

The 14th century saw a general decline in the fortunes of local cloth manufacture: between 1318 and 1328 there were no recorded fulling mills in the town. Cloth was still made in Witney, however, and in the 15th century the trade began to grow again. The Bishop of Winchester built a new fulling mill at Woodford Mill in 1458 and by the 1460s imported woad, madder and alum (all ingredients used in cloth dyeing) were being brought to Witney from Southampton [7].

Apart from the Bishops' wool concerns, independent wool merchants and cloth makers were also attracted to Witney and West Oxfordshire by the early 15th century. They ranged from small family businesses engaged in cloth making processes to much larger operators who were mainly wool dealers. A lot of these wool families became very rich, like the Wenmans, Hoods and Fermors. They erected impressive houses and buildings and many of the churches, monuments, market halls and grand town houses in Witney, Chipping Norton and Burford that you can still see today were built with wealth created from the woolly backs of sheep.

16th century

Witney's economic life was dominated by its expanding cloth trade from the 16th century onwards [8]. The cloth produced was largely undyed broadcloth, a fairly heavy, felted material used for making many different items including clothing, blankets, covers, awnings and tilts [9]. Undyed broadcloth was at this time the country's principal export [10]. Some linen and narrow cloth was also made in Witney.

17th century

It was in the 17th century that Witney really began to specialise in and become known for good quality blankets. 'Blanketing' was a particular type of broadcloth usually made from coarse fell wool; blankets were made locally before this date (there is a record of a member of the Collier family selling 30 blankets to the Earl of Leicester in 1584, for example) but it was only after the 1620s that Witney clothiers dealt in large quantities of blankets and blanket yarn [11].

17th century trade token from Witney showing two shuttles.

By the 1670s Witney blanket makers had established new markets for their products in North America and Africa, as well as having a good domestic reputation. By now carts were travelling every week from Witney to London loaded with blankets to sell and export, and returning laden with raw wool. The Hudson Bay Trading Company was established in 1670 and placed an order for 45 pairs of 'Oxfordshire' blankets in 1681; it was to become an important client of Witney manufacturers in the future [13].

In 1677 the historian Dr Robert Plot wrote that Witney blankets 'are esteemed so far beyond all others, that this place has engrossed the whole trade of the Nation for this Commodity'. He also recorded that the Witney Industry employed at least 3,000 poor 'from 8 years old to decrepit old age'.

18th century

Portrait of Queen Anne given to the Blanket Weavers' Company by

Lord Harcourt, and displayed in the Blanket Hall.

It has been estimated that when the Company was set up there would have been about 180 looms working in and around Witney directly employing around 360 people, with perhaps a further 2,000 or so men, women and children working in supporting roles as carders, spinners and quill winders [14].

Trade with the Hudson Bay Company increased from the early 18th century. Coarse blankets were sold to North America and finer ones to Spain and Portugal. The blanket trade generally seems to have expanded from the mid-18th century onwards, four or five waggon loads being sent to London every week in the 1760s.

An element of mechanisation had appeared in the local industry by the late 18th century: in 1782 the Blanket Weavers' Company bought a horse-powered 'rowing' machine for raising the nap on blankets (a job previously done by hand) and about 1800 Thomas Early is thought to have been the first person to use the flying shuttle in Witney.

19th century

The 19th century sees the Witney blanket trade transform from involving over 70 different businesses to become concentrated into the hands of less than 12 family firms by 1820 and only two by 1899. The 12 included members of the Collier, Early and Marriott families, some of whom were to expand their businesses to become large, commercial firms operating a factory system.

The introduction of water-powered spinning machinery by Edmund Wright to New Mill in 1808 really signalled the beginnings of industrialisation in Witney. More machinery for carding and scribbling, made in Rochdale, Lancashire, was bought and installed in New Mill by 1818. These changes did not of course meet with universal approval because of the unemployment and hardship that they created for the many cottage-based workers.

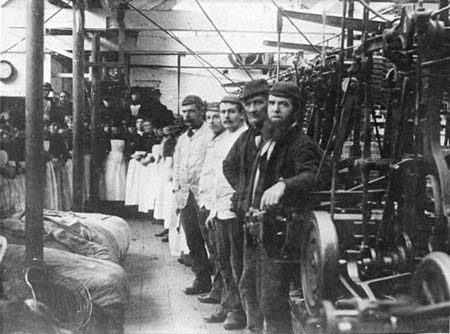

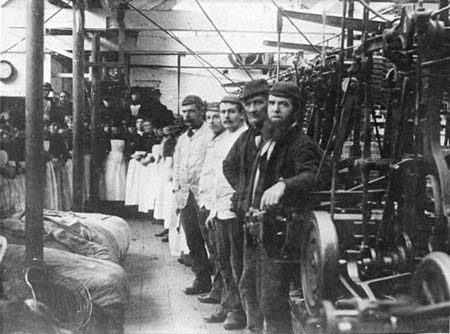

Group of men and women in the weaving shed at a Witney mill,

late 19th century.

Despite several trade depressions during the period, the blanket makers continued to prosper by successfully chasing new markets, introducing new working methods and machinery, and by co-operation and support between the remaining firms. Maintaining their established good reputations and trading links was also important, especially with the Hudson Bay Company.

By 1895 only two blanket manufacturers dominated most of the blanket business in the area: Charles Early and Co. with several premises and William Smith and Co. operating from Bridge Street and Crawley Mills.

20th century

Witney was still largely dependent on the blanket industry at the start of the century and there many workers were employed in it: around 1922 there were at least 1,000 workers and 400 looms in operation. By 1937 Witney was producing 700,000 pairs of blankets every year, over a fifth of the national output [16].

Two new companies established themselves in Witney in the 20th century. James Marriott established his successful blanket wholesale business at Mount Mills in 1900 and one of the biggest blanket making firms in Britain, James Walker and Company of Yorkshire, built a new factory at a site called 'The Crofts' by 1933. Walker's came to the town to capitalise on the good reputation of Witney blankets: by a legal judgement of 1909, only blankets actually made in Witney could be called or labelled genuine 'Witney blankets'.

In the Second World War some factories were closed while others concentrated on producing blankets for the armed forces.

By 1950 Witney firms were producing a quarter of all of the country's blankets. Old-fashioned manufacturing processes such as sulphur bleaching and outdoor tentering had died out at this time.

An Early's worker feeding cloth into a tandem gig, for raising

the nap on the blankets (copyright Mike French).

Despite these changes the industry declined from the early 1970s onwards, mainly due to the popularity of the duvet over blankets. Smith and Philips' closed in 1975, the Witney Blanket Company by 1977, and Walker's in 1980. The firms of Early and Marriott had merged in 1960 to enable them to face increased competition and managed to sustain their business and name until sadly closing in 2002, becoming the last firm to make genuine Witney Blankets.

|