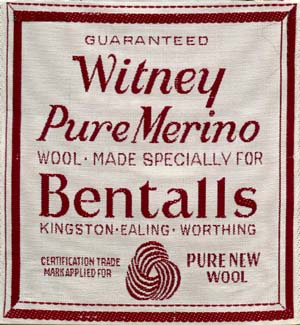

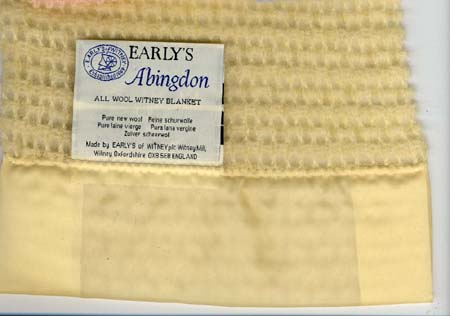

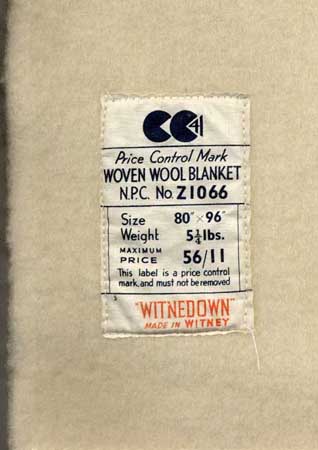

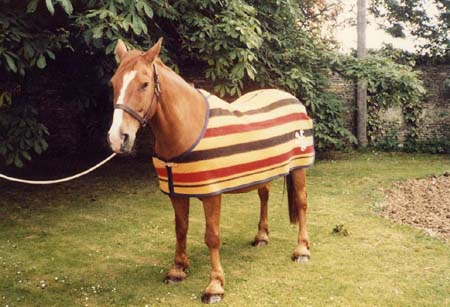

What kinds of blankets were made in Witney?The life of the Oxfordshire town of Witney became dominated by the business of cloth and blanket making from the early 16th century; through many changes and varying fortunes, that trade was to continue until 2002. During those four hundred years many different types of blankets were made there in an astonishing array of sizes, weights, qualities, colours, patterns and uses. They also differed according to which blanket makers or firms produced them, what type of process they were made by and what the buyers' requirements were. Here are some of the types of blankets that were important products of the Witney industry: All-wool woven blankets The majority of blankets varied from off-white to cream depending on whether they had been bleached or not; often they were made with coloured stripes or headings inserted at each end. A certain amount of one-colour dyed blankets were also produced in the 19th century, becoming much more common in the 20th century. The blanket stitch finishing (known as whipping) on the cut ends of each blanket might also be coloured, though some were bound with satin or synthetic material instead. After the Second World War the output of dyed blankets increased. A high proportion of these blankets were sold for domestic use in Britain and abroad. Some blankets were labelled only with the name of the company that placed the order for them (often a department store or retailer) and do not show which Witney blanket company manufactured them, but nearly all will have the all important word 'Witney' somewhere on the label. Point blankets Point blankets were always made from wool and had one or more 'headings' or bands of colour at either end, but most importantly had several short lines known as 'points' sewn or woven into one corner; the number of points on a blanket indicated its size and therefore its value [2]. Aside from these essentials they were made in a variety of colours and patterns over the years; a white background with indigo, red, green, and yellow bands was to become one of the best known or 'classic' point designs. Victorian and 20th century point blankets often have labels which identify them as a 'Witney Point Blanket' and Early's adopted a trademark of an Native American wearing a feather headdress which they used on their points for much of the 20th century. Smith and Philips' of Bridge Street also made points; their trademark was a globe with the words 'Witnedown Blankets Cover the World'. Cellular blankets Early's experimented with making cellular blankets in 1952, becoming the one of the first companies to reduce the price of these goods to an affordable level. By 1955 they were making large quantities in both cotton and wool. White cotton cellular blankets were much in demand by hospitals because they could stand up to the high temperature washing needed to prevent the spread of infection. Woollen mixture cellular blankets were produced in a range of colours by several Witney firms and sold internationally. Cellular blankets were also a popular choice for cot blankets. Fiberwoven blankets Fiberweavers would not work well with pure wool so Fiberwoven blankets were either 100% synthetic or had a high proportion of synthetic fibres. They were produced in many colours and patterns and could also be screen printed: floral motifs, cartoon characters and pop stars including The Beatles all appeared on them. Their introduction coincided with a renewed wave of interest in home decoration and design in the 1960s and 1970s and they became much more of a fashion item than the traditional wool blankets, often bought to match the decorative scheme of a room. Airlines, shipping companies, hotels and other mass consumers of blankets were regular purchasers of Fiberwoven goods. Knitted blankets Government order, military and hospital blankets  Blanket with 'CC41' Utility mark logo, made in or just after the Second World War to a lower specification than blankets made before the War. Hospital blankets had long been a Witney product even before the introduction of cotton cellular blankets in the 1950s. In 1823 the Steward of St Thomas' Hospital, London, placed an order for 50 pairs of blankets, 'of similar quality and weight as those manufactured for Guy's Hospital' [4]. Horse blankets  Replica of one of the pair of horse blankets made as a wedding present for Prince Charles and Lady Diana in 1981. Electric blankets

|

|

| References [1] Plummer and Early 1969: p40 [2] Tichenor 2003: p7 [3] Townley 2004: p84 [4] Plummer and Early 1969: p70 [5] Plummer and Early 1969: p147, p163 |

Listen: Download audio file Peter Baston, a former wool buyer for Marriott's and Early and Marriott Ltd, describes the range of products that were made at Marriott's (79Kb). Download audio file Mike French, former engineer to Early's blanket manufacturers, recalls the secrecy that surrounded the introduction of fibreweaving machines (94Kb). |