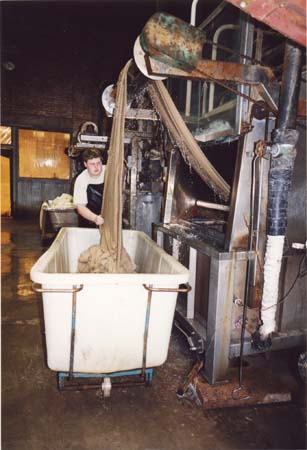

Scouring

A stockful being washed in a machine. A worker in an apron

supervises and guides the blanket into a white plastic trolley.

Witney Mill, 2002.

Scouring involves cleaning the woven blanket of the dirt and

grease accumulated during the previous production processes.

This is the first stage of the scouring and milling processes.

There are two ways of doing it, using either a combined

scouring/milling machine or two different machines, one for

scouring and one for milling.

Firstly the complete stockful will be fed into the scouring

machine and the two ends sewn together so as there is one

continuous length of blanket. In this machine there are two

tension rollers that the stockful has to run through. The first

treatment in this machine is to wet the cloth with a solution of

sodium carbonate, this converts the oil that was sprayed on

during the willeying process into soap which will remove all the

dirt and grease from the cloth. After a while warm water is

added, a lather is worked up and the cloth is washed for about

30 minutes. The drain is now opened in the machine for the soapy

water to escape and clean cold water is sprayed onto the cloth

to remove all traces of soap.

Mike French

|