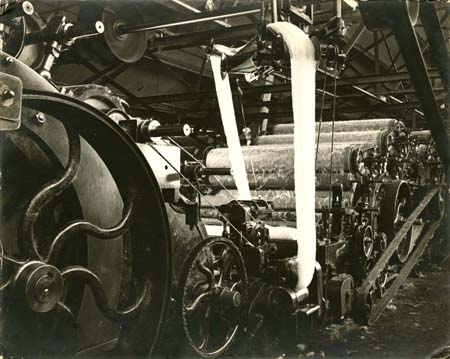

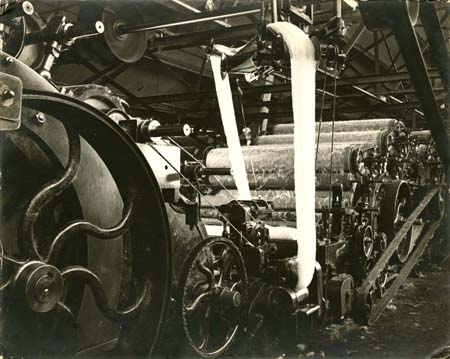

Carding

Carding engines at Smith's Bridge Street Mill, c1940s. There are three reasons for carding the fibre: the opening of

the wool staples and the separation of all fibres from each

other; cleaning of the fibre by the removal of as much vegetable

matter as possible; arrangement of the fibre into continuous

'slivers' of a uniform thickness throughout their length. The

carding engine consists of two sections, the 'scribbler' and the

'carder', each section normally being made up of two large

cylinders (swifts) each containing a set of four 'worker'

rollers and four 'stripper' rollers. The cylinders and rollers

are covered by a special wire-covered carding material, called

'carding cloth'.

The fibre is placed by hand into a hopper at the rear of the

carding engine, from where it is transferred into a scale pan by

a revolving spiked lattice feed sheet. When the scale pan is

full, the lattice sheet stops. The scale pan is then

automatically inverted and the fibre drops onto another feed

sheet for delivery to the scribbler cylinder. Once empty the

scale pan reverts to its original position and the delivery

lattice starts again. This system ensures that accurately

weighed quantities of fibre are fed onto the feed sheet at

regular intervals.

The fibre is carried forward onto the first swift of the

scribbler machine; as the swift revolves at very high speed, the

four sets of worker and stripper rollers carry out their own

operations in turn. The worker and stripper rollers run at a

slower speed than the swift cylinder. The workers hold the fibre

while the faster moving swift combs them, as the worker slowly

revolves it will remove all the fibre from the swift. (The

remainder of the fibre is continually being passed to the next

set of rollers by the swift). The stripper rollers then remove

the fibre from the worker rollers and replace it back onto the

swift. This process of working, combing and stripping continues

throughout the length of the carding engine.

As the fibre passes through the last section of the carding

engine it is combed off the swift cylinder and a very fine web

of material is formed. From here the web of fibre is guided (in

equal quantities and widths) onto sets of leather belts about

one inch wide; from these belts the web will pass between a pair

of wide reciprocating and revolving rubber or leather belts

which gently rub the web of fibre together and consolidate them

into soft strands of fibre. These strands will be strong enough

to be wound onto 'condenser' bobbins (usually eight in number,

each containing fourteen strands across their width). When full

these bobbins are removed from the carding engine and placed in

racks to await the next process which is spinning, in which the

soft web of fibre will be spun into strong yarn.

Mike French

|