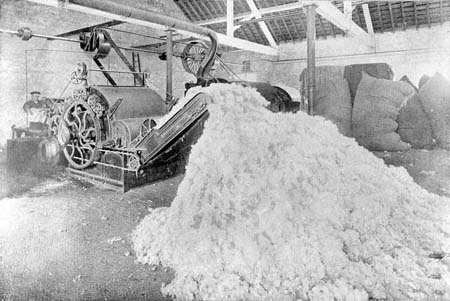

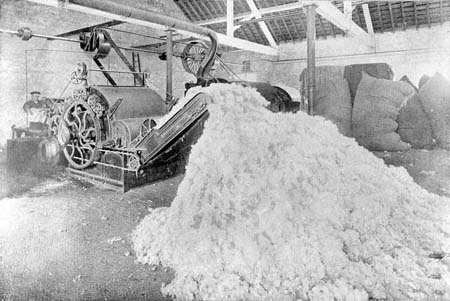

Willeying

Willeying at an Early's mill, 1898. Once the right blend of wool had been made up it was 'willeyed'.

The willeying machine opened up or pulled apart the wool fibres

and prepared it for carding. It was called a 'willey' or

'willow' probably because the process was originally carried out

with cylinders made of willow basket work.

The wool was generally first fed into the 'shake willey' which

shook the wool while cylinders fitted with iron spikes beat and

roughly opened it out. This got rid of much of the dust and dirt

(known as 'nips') which were then blown away by a fan. This

process was used particularly for wool blends which were very

dusty, wool that was greasy or dirty would cause the dust to

stick both to the wool and to the machine and so was not always

put through this initial stage.

The wool was then fed to the second willeying machine or

'teazer' (known in Witney as a 'Fearnought') which had its

cylinders closely set with smaller curved teeth that opened out

the wool fibres even more. Wool oil was applied to the wool to

prevent the fibres being broken up by the carding machine and to

help lubricate them for spinning.

Clare Sumner

|