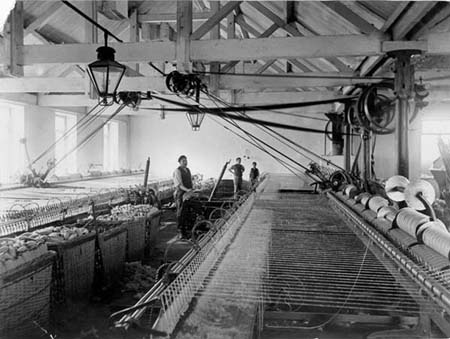

Spinning

Spinning mules in operation at a Witney mill, 1898. This is the process by which the slivers from the carding

process are stretched and twisted into yarn ready to be woven.

Spinning was done on an automatic machine called a spinning mule

or 'self-actor'.

The large bobbins taken from the carding engine were placed in a

row along the back of the spinning mule. The mule consisted of a

fixed frame holding the large bobbins and a moving carriage at

the front holding hundreds of small bobbins on to which the

thread was wound. The carriage moved outwards on rails to

stretch the yarn while at the same time the small bobbins

revolved to add twist to it, strengthening the thread. The

carriage then reversed direction but the bobbins continued to

revolve, this time to wind the yarn on to them. The whole

process was repeated until the bobbins were full. The stretch

and the amount of twist given to the thread depended on the

quality of yarn desired and whether it was intended for the weft

or the warp threads.

The local name for bobbins in Witney was a 'fosset'.

Clare Sumner

|