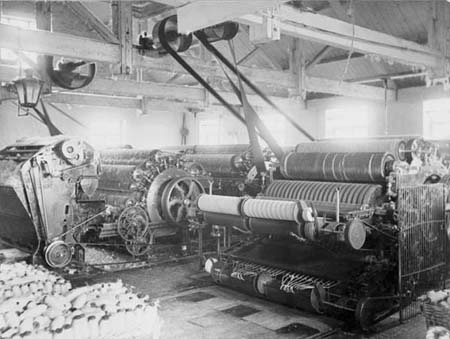

Scribbling

Scribbling and carding engines, 1898. The scribbler is the

machine furthest from the camera, with the automatic weigher at

its left side.

The scribbler was the first part of a group of machines known

collectively as the carding engine. These were the largest and

most complex machines used in the blanket making process.

An automatic weigher and feeder delivered regular and even

quantities of wool to the scribbler. The scribbler itself

consisted of a large roller called a swift which was covered

with 'card clothing'; this was leather sheet stuck full of bent

steel wires or 'fingers'. The wires were graduated in size from

coarse to fine and worked the different sizes of fibre. As the

swift revolved it carried the wool under several pairs of

smaller worker and stripper rollers. The workers opened out and

separated any hard knots of wool, as well as allowing dirt

particles to fall out from the web of fibres. The strippers

removed the carded wool from the workers and returned it to the

swift to be worked on by the next pair of rollers.

At the end of the scribbler was the 'doffer' roller which

stripped the wool from the swift. A rapidly moving blade called

a doffer comb removed a fine web of wool fibres from the doffer

in a continuous sheet, which was then picked up by the 'scotch

feed' mechanism and delivered to the carder.

Clare Sumner

|