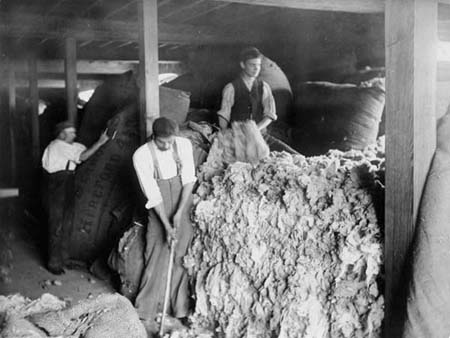

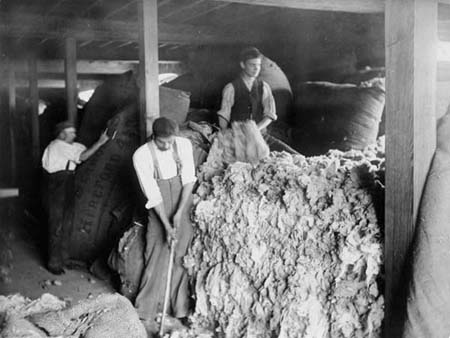

Scouring

Unpacking wool at a Witney mill, early 20th century. This is the cleaning of the raw wool fibre which takes place

after the wool has been sorted into different qualities.

Although sheep were washed or dipped before they were sheared,

between 30% and 70% of the weight of the raw fleece wool could

still be made up of particles of grease (lanolin), dirt and

other impurities such as grass, thorns and dead hair - even

after it had been sorted. One of the main skills wool buyers

needed was an ability to judge the proportions of wool to dirt

in the different wools on offer. A lot of the impurities were

removed by the scouring process, the aim being to leave behind a

soft, fine-textured, pure fibre that would spin up into in an

even thread. Before industrialisation, scouring generally took

place in fulling mills where wool was soaked in stale urine

(known as 'lant') or fullers' earth to clean it. If wool was

not properly scoured then it could cause problems later when it

came to carding, dyeing and spinning.

Scouring machines were used in some mills in Britain, which

bathed the wool in successive warm detergent rinses and carried

away all the dirt without matting the fibres together. Until the

middle years of the 20th century it appears that Early's did

very little scouring on their premises and treated the wool 'in

the grease' and this seems to have been true of the other Witney

blanket makers. A small proportion of wools were scoured,

though: Merino wool (used for the finest quality blankets) as

this had a very high percentage of grease in it, and also wool

which was going to be dyed a colour in order to form the

'laces' or stripes in a blanket. Processing wool this way meant

that a lot of machine cleaning had to take place, especially if

wool bought from fellmongers had a high proportion of lime in it

as this produced a putty-like substance. If cleaner wool was

required this was usually ordered from, and carried out by, the

wool supplier or fellmonger although Early's also had a small

scouring machine. An acid carbonising treatment would be used to

remove any vegetable matter that still remained in the wool

after it had been cleaned.

Clare Sumner

|