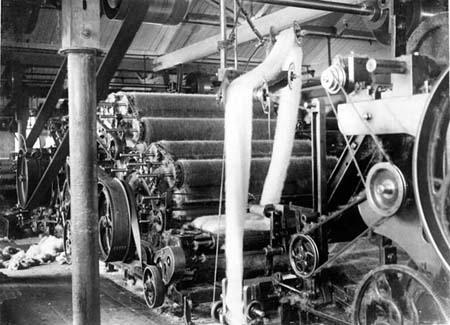

Carding and condensing

A carding engine, 1898. A rope of scribbled wool is being

delivered by the scotch feed.

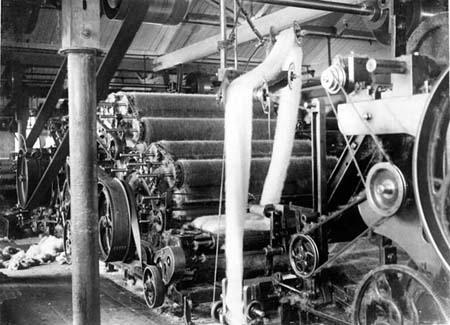

After being roughly carded on the scribbler, the wool was fed

directly into the fine carding engine known simply as the

carder. This machine was very similar to the scribbler, but the

wire teeth were finer. The wool benefited from being worked a

second time as more knots and tangles were removed. The

resulting fine web of wool was stripped from the carder and

passed straight into the condenser.

The condenser had a roller known as a 'ring doffer', which was

ringed round with bands of wire teeth with gaps between each

band. This condensed the carded wool into narrow strips which

were then rubbed between leather belts to form loose ropes of

wool known as 'slivers'. These were wound onto long wooden

bobbins and sent off to the spinning department.

It was partly because of the use of un-scoured wool that Early's

continued to use a double-doffer condensing machine as this

coped better with dirty wool.

Clare Sumner

|